Or consider an OptiSpark Tuneup

Or review the LT1 Engine Electronic Difference between the OPTIs & ECMs

Or review the LT1 Engine Fuel System Differences (Batch vs Sequental)

Sélection d’un remplaçant Optispark

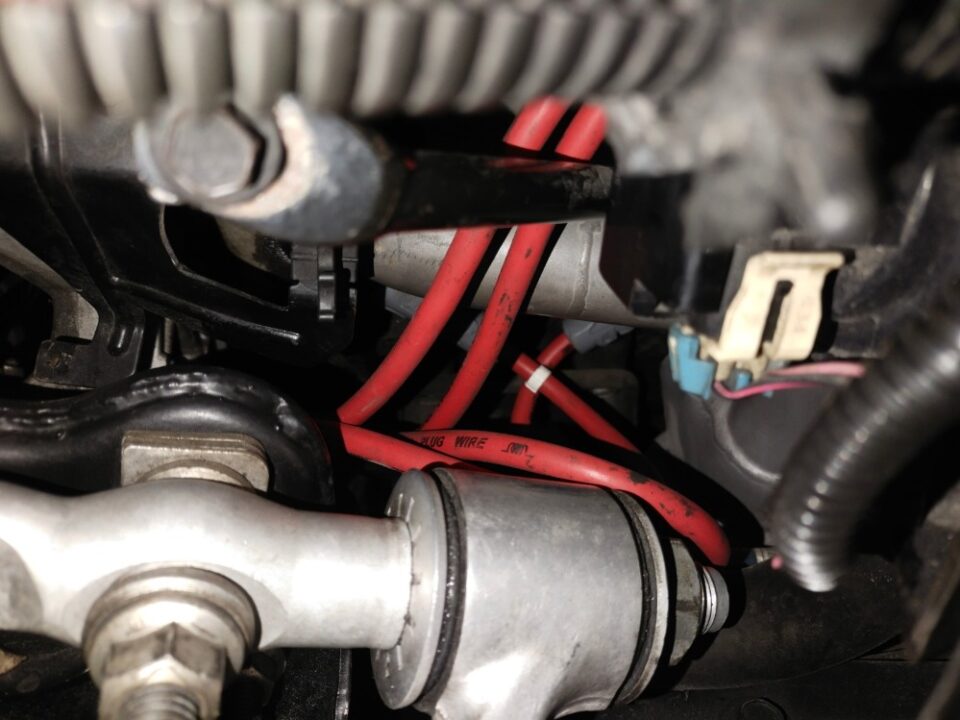

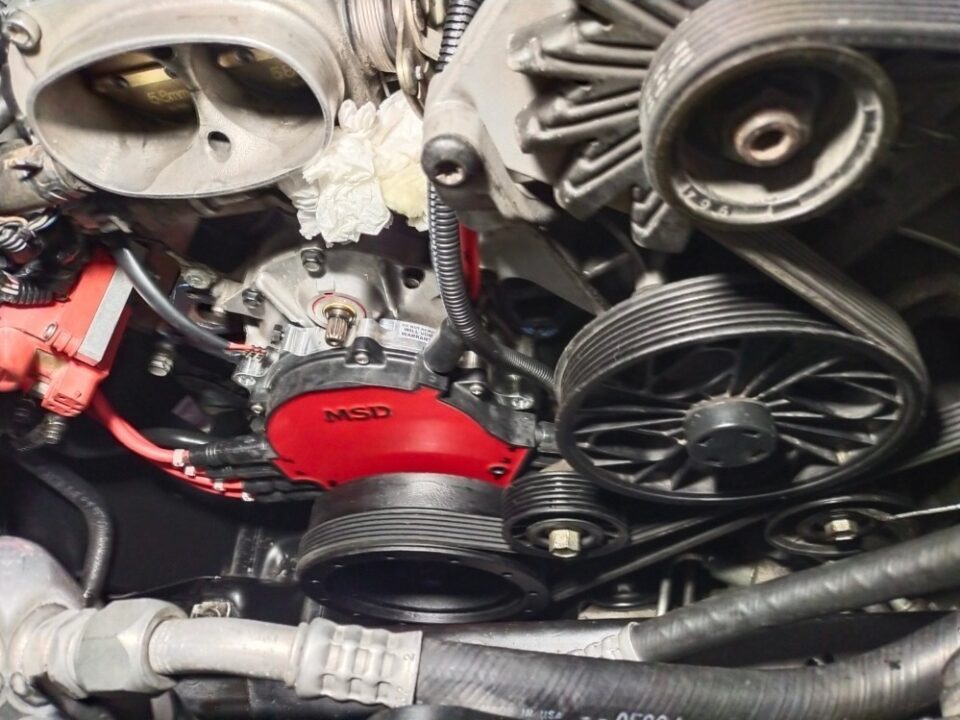

C’est toujours un jour triste quand le Prince Noir tombe malade – mais il sera bientôt opérationnel car son traitement sera 1) un ensemble de MSD Ignition 32179 – MSD 8,5 mm Super Conductor Spark Plug Wire Sets, 2) MSD Ignition 8381 – Distributeurs MSD Pro-Billet LT1 et 3) MSD Ignition 8843 – Séparateurs de fils MSD Pro-Clamp.

En outre, peut-être la décision de remplacer la pompe à eau de 30 ans par une pompe Flow Kooler ….

https://flowkoolerwaterpumps.com/

les composants de remplacement

Optispark – Un gros problème avec le V8 5.7 LT1 de Chevy

Allez sur n’importe quelle piste d’accélération en Amérique n’importe quelle nuit et vous verrez beaucoup de Camaros et Firebirds de quatrième génération. Un drag racer naturel avec leur poids assez léger, leur propulsion arrière, leurs transmissions solides et leur suspension simple, les voitures “F-body” du milieu des années 90 comportaient également un gros V8 LT1 de 350 pouces cubes. Ce moteur comportait un nouveau distributeur conception appelée Optispark qui était en proie à des problèmes.Si vous possédez une voiture LT1, voici ce qu’il faut surveiller et ce qu’il faut faire lorsque cet Opti tombe en panne.

Le V8 Chevy (SBC) original à petit bloc a été construit pendant des décennies, du milieu des années 1950 aux années 1990. Mais les temps qui changent exigent des conceptions changeantes. L’augmentation de l’efficacité, de la puissance et de la réduction des émissions était le nom du jeu à la fin des années 1980 et au début des années 1990, et le distributeur HEI entraîné par arbre à cames sur le SBC n’était plus efficace. GM a modifié la conception du petit bloc LT1 de génération II avec des têtes en aluminium et un refroidissement à flux inversé, ce qui signifie que les têtes ont été refroidies avant le bloc moteur. Cela a permis des taux de compression plus élevés, ce qui a entraîné une plus grande consommation d’énergie et d’essence et une réduction des émissions. L’un des autres changements majeurs a été le distributeur.

Alors qu’un petit bloc Chevy V8 traditionnel à injection de carburant avait le distributeur à l’arrière du bloc moteur, le LT1 comportait un nouveau type de capteur optique placé à l’avant du moteur. Ce capteur est capable de “voir” la lumière LED passer à travers une roue de reluctor en rotation (nom de fantaisie pour le disque fendu) par incréments d’un degré. Alors que les modules de commande électroniques précédents n’avaient aucune idée du cylindre qui tirait jusqu’à ce que le rotor ait dépassé le point de ramassage , l’ECM du LT1 a pu savoir où se trouve chaque piston et quel cylindre se déclenchera ensuite.Lorsque l’ECM connaît la véritable position de l’arbre à cames, le régime moteur, etc., il peut affiner le calage de l’allumage pour chaque cylindre dans une large gamme de conditions L’Optispark est toujours une excellente idée et un véritable bond en avant dans la technologie des moteurs.

Bien qu’il soit avancé pour l’époque, il ne faut pas le confondre avec le moteur LT1 de génération actuelle qui équipe la Camaro de sixième génération. L’ancien LT1 n’était installé que dans le compartiment moteur des modèles Camaro et Firebird V8 du milieu des années 90, ainsi que la Corvette C4 et les versions à plus petite cylindrée intégrées aux Chevy Caprice et Buick Roadmaster. Le LT1 propulsait également des voitures de police et des taxis, et n’avait vraiment qu’un seul problème.

Problèmes Optispark

Bien qu’il ait parfaitement fonctionné dans un laboratoire ou lors de journées ensoleillées sur les terrains d’essai de GM, un montage bas à l’avant du moteur signifiait que l’Opti souffrait beaucoup plus de l’exposition à l’eau de la route, au sable et au sel que le distributeur typique. Étant sous la pompe à eau, si cette pièce tombait en panne, elle emportait le distributeur avec elle. Même un tuyau de radiateur de 20 $ pourrait se fendre et coûter des centaines de dollars en pièces lorsqu’il imbibe l’Opti de liquide de refroidissement. Cela a été aggravé par le fait que les trous de ventilation de l’usine étaient trop petits, ce qui provoque une accumulation d’ozone et de la corrosion, entraînant des ratés du moteur. Il ne permet pas non plus à l’humidité de s’échapper, donc si le véhicule est resté assis pendant quelques semaines, cette humidité s’est propagée à travers le distributeur au démarrage. Certains propriétaires ont même rapporté avoir retiré l’Opti et en avoir fait couler de l’eau !

Avec le recul, c’est une exécution de conception hilarante, car la moindre eau provenant du nettoyage d’un compartiment moteur peut causer des problèmes d’Optispark, parfois dès 20 000 milles. De plus, il a une conception conventionnelle de capuchon et de rotor, mais en raison de l’emplacement derrière la pompe à eau, ils sont beaucoup plus difficiles à entretenir qu’un distributeur conventionnel. De nombreux propriétaires ont supposé que le capuchon et le rotor du LT1 étaient des unités à vie qui n’avaient pas besoin d’entretien, et n’y ont prêté attention que lorsque l’Opti avait besoin d’être remplacé.

La “solution” de GM consistait à remplacer l’unité défaillante par une autre Opti présentant les mêmes défauts et présentant la même panne. Sous garantie, cela ne coûte rien au propriétaire, mais les garanties d’usine ont expiré depuis longtemps, ce qui fait que cette réparation a coûté plusieurs centaines de dollars chez le concessionnaire.

Les symptômes d’un Optispark défaillant sont généralement de mauvaises performances du moteur, une hésitation à l’accélération, des trébuchements et des vibrations excessives, des ratés d’allumage audibles et les codes de “vérification du moteur” associés.

Le correctif Optispark

Les propriétaires ont rapidement réalisé les problèmes avec leur distributeur et ont utilisé un foret .187 pour agrandir les trous de vidange d’usine et ont pris une lame de rasoir à l’intérieur du capuchon pour améliorer la circulation de l’air. Bien que cette solution homebrew ait été quelque peu efficace, il s’agissait de correctifs de pansement pour les pièces généralement à kilométrage élevé. Fondamentalement, cela représentait beaucoup de travail et n’a pas entièrement résolu le problème, alors pourquoi le faire à moitié ?

Au lieu de cela, la meilleure solution rentable consiste à opter pour des pièces de rechange de qualité supérieure. MSD, CarQuest, BWD, Pertronix et d’autres fabriquent des distributeurs optiques de remplacement plus fiables que l’unité d’origine, à un prix inférieur. Les trous de vidange sur le fond sont plus grands que les unités d’usine, et une nouvelle conception ventilée utilise une source d’air frais et un tube à vide pour empêcher les gaz et l’humidité de s’accumuler sous le capuchon. Ces conceptions sont également plus résistantes à l’eau, ce qui vous permet de laver le moteur pour un éclat de compartiment moteur de show-car.

Si vous vous attaquez à celui-ci vous-même, notez simplement qu’il y a six boulons qui maintiennent la pompe à eau, pas seulement les quatre que vous pouvez voir. N’essayez pas de le retirer après en avoir dévissé seulement quatre. De plus, le nouvel Opti devrait entrer à la main. Utilisez une bonne quantité de silicone et ne forcez pas pour le mettre en place, car cela signifie qu’il est mal aligné. Enfin, à long terme

source | Rich Niewiroski Jr.

Optispark a remplacé HEI

Go to any dragstrip in America on any given night, and you will see a lot of fourth-generation Camaros and Firebirds. A natural drag racer with their fairly light weight, rear wheel drive, strong transmissions, and simple suspension, the mid-’90s “F-body” cars also featured a stout 350-cubic-inch LT1 V8. This engine featured a new distributor design called Optispark that was plagued with issues. If you own an LT1 car, here’s what to watch for and what to do when that Opti fails.

The original small-block Chevy (SBC) V8 was built for decades, spanning from the mid-1950s through the 1990s. But changing times demand changing designs. Increasing efficiency, horsepower, and emissions reduction was the name of the game in the late 1980s and early 1990s, and the camshaft-driven HEI distributor on the SBC was no longer effective. GM changed the design for the Generation II LT1 small block with aluminum heads and reverse-flow cooling, meaning the heads were cooled before the engine block. This allowed higher compression ratios, resulting in more power and gas mileage, and reduced emissions. One of the other major changes was the distributor.

While a traditional fuel-injected small-block Chevy V8 had the distributor at the rear of the engine block, the LT1 featured a new type of optical sensor placed on the front of the engine. This sensor is able to “see” the LED light passing through a spinning reluctor wheel (fancy name for slotted disc) in one-degree increments. While the previous Electronic Control Modules had no idea which cylinder was firing until the rotor passed the pickup point, the LT1’s ECM was able to know where each piston is located and which cylinder will fire next. When the ECM knows the true camshaft position, engine speed and such, it can fine-tune ignition timing for each cylinder under a wide range of conditions. The Optispark is still a great idea and a genuine leap forward in engine technology.

While it was advanced for the time, it should not be confused with the current-generation LT1 engine powering the sixth-generation Camaro. The old LT1 was only stuffed into the engine bay of the mid-’90s Camaro and Firebird V8 models, plus the C4 Corvette and smaller displacement versions made it into the Chevy Caprice and Buick Roadmaster. The LT1 powered police cars and taxis, too, and really only had one problem.

Optispark Problems

While it worked perfectly in a lab or on bright, sunny days at GM’s proving grounds, low mounting on the front of the engine meant the Opti suffered from exposure to road water, grit, and salt far more than the typical distributor. Being under the water pump, if that part failed, it took the distributor out with it. Even a $20 radiator hose could split and cost hundreds of dollars in parts when it soaks the Opti with coolant. This was compounded with the factory ventilation holes being too small, which causes ozone buildup and corrosion, leading to engine misfires. It also doesn’t allow moisture to escape, so if the vehicle sat for a few weeks, that moisture was spread through the distributor on startup. Some owners even reported pulling off the Opti and having water pour out of it!

Looking back, it’s a hilariously poor design execution, as the slightest bit of water from cleaning an engine bay can cause Optispark problems, sometimes as early as 20,000 miles. Also, it has a conventional cap and rotor design, but due to the location behind the water pump, they are much harder to service than a conventional distributor. Many owners assumed the LT1 cap and rotor were lifetime units that didn’t need servicing, and only paid attention to it when the Opti needed replacement.

GM’s “solution” was to replace the failing unit with another Opti that has the same faults and will have the same failure. Under warranty, this costs the owner nothing, but the factory warranties have long ago expired, making this repair cost several hundred dollars at the dealership.

Symptoms of a failing Optispark are typically poor engine performance, hesitation on accelerating, stumbling and excessive vibration, audible misfiring, and the associated “check engine” codes.

The Optispark Fix

Owners quickly realized the issues with their distributor and used a .187 drill bit to enlarge the factory drain holes and took a razor blade to the inside of the cap to improve air flow. While this homebrew solution was somewhat effective, these were Band-Aid fixes to usually high-mileage parts. Basically, it was a lot of work and didn’t entirely solve the problem, so why do it halfway?

Instead, the best cost-effective solution is to go with a superior aftermarket parts. MSD, CarQuest, BWD, Pertronix, and others build replacement optical distributors that are more reliable than the original unit, for a lower price. The drain holes on the bottom are larger than factory units, and a newer vented design uses a fresh air source and vacuum tube to keep gases and moisture from building up under the cap. These designs are more water resistant, too, allowing you to wash the engine for a show-car engine bay shine.

If you tackle this one yourself, just note that there are six bolts keeping the water pump on, not just the four you can see. Don’t try to pry it off after unbolting only four. Also, the new Opti should go in by hand. Use a good amount of silicone and don’t force it into position, as that means it’s misaligned. Finally, for long-term reliability, change the water pump and the intake manifold gasket at the same time as an Opti replacement.

The LT1 is a solid engine, with horsepower and torque to spare, and a large aftermarket for performance upgrades. By fixing this one issue, it should be set for many more years of trouble-free driving.

Last updated June 6, 2018

GM RECALL DOCUMENT – 92 OPTIs https://www.corvetteactioncenter.com/tech/knowledgebase/article/1992-corvette-recall-optispark-distributor-554.html

Photos Part 1 of 2 – old parts removed

Photos Part 2 of 2 – New Part Installed

Commentaires des lecteurs

Facebook member Comments

The following was provided by Facebook follower (Must Stang) – https://www.facebook.com/must.stang.54/ —

Take the cover off the Optispark and put a very small amount of high temperature lock tight under the two tiny screws. Since the Optispark is sideways it will keep the small screws in place. I have seen screws come out and they can damage the optispark then you have to replace it again.

I also put a very small amount around my optispark to keep any water from getting behind it (Me? Not sure about this). Also, on my 95 there is a tiny hole under the water pump that can drip on your optispark and cause problems. You can use a rubber hose and run it around under the optispark so it never drips on it.

Also, on my 95 there are three holes but it will only lines up one way. If you leave the cover off you can turn it from inside to get the correct alignment. If you put it back on wrong your car misfires and never starts. The optispark takes a lot of time to replace. You don’t want to do it twice.

If your car shuts off and only starts after it cools down it’s not the optispark. It’s usually a bad fuel injector most of the time. The harmonic balancer can get stuck on your car. But you have to take it off to change the optispark. Some you can tap off. Some you can loosen the three screws without taking them off. Take a fuse out so it will only turn over and just turn the key and just bump it. Only a bump. You don’t want to turn it too much. Sometimes it will break loose. But the first to do is to spray it with nut buster and leave it overnight. I can’t tell how good the stuff works.

There is another way, but you have to modify a puller from Amazon. Unfortunately, it’s too wide to fit down to the harmonic balancer. So, you have to shorten the teeth some so it will go right down in there. The you can use a wrench puller and it will come off without having to jack the car up. Works like a charm. I got a pic before a shorten it. But it will work great. Just modify it. Look at the photo to see how far out the hooks are at the bottom. If you take it to a machine shop have them cut some space out – then welded back on and it will fit between your frame and harmonic balancer then lock on and just simply turn the bolt. There is a small place where the bolt will fit in to the puller. The other photo is where your optispark fits. You see there are there other possibilities, but it only goes one way. With the cover off you turn it so it will drop into the correct spot. There are two holes that look alike, but its not them – Its the other one. After you line it up you put all the bolts back on and don’t have to guess if it is correct.

Optispark fits into the left hole and It looks different from the other two. If you bolt it on wrong your car will not start and only misfires

Lol I meant right hole. Remember it is the hole that looks different. Keep in mind it is this way on a 1995 corvette.

Regardless of the Optispark you buy including the MSD, be sure to take off the cover and add some high temperature lock tight under all the small screws inside. Sometimes they aren’t even tight. If they come out, they can damage the optispark. Mine is vented. I also added a little lock tight around the edges of the optispark so no moisture can get in. You will also need to take off the cover to line up the optispark to the correct position. There are three places it could fit into on my 95 LT1 as they look alike. But it is the one that looks different than the other two. Note the photo 3, it lines up to the top in this Photo. If you happen to put your optispark into one of the other spots your engine will backfire and will not start.

OPTISPARK TUNEUP

Tuning Up the Optispark on a 1992-1993 Corvette LT1

The Optispark system in the 1992-1993 Corvette LT1 can be maintained and tuned up effectively following these steps:

- Cap and Rotor Maintenance:

- Use MSD Part# 8481 to replace the cap and rotor. This kit also includes a vent kit to upgrade or repair the spline drive and pin drive units.

- Disassemble and Clean:

- Remove the Optispark unit, disassemble it, and thoroughly clean all components. Periodic cleaning can extend the life of the Optispark and maintain its performance.

- Lubricate or Replace the Bearing:

- The internal bearing of the Optispark can be lubricated or replaced if necessary. This will help in keeping the mechanism running smoothly.

- Rotor Screw Maintenance:

- Apply Loctite Blue on the rotor screws to ensure they stay secure during operation.

- Seal the Cap:

- Use Permatex RTV to seal the Optispark cap thoroughly. This prevents moisture from entering and damaging the internal components.

- Upgrade Related Components:

- Consider replacing the Optispark harness, timing cover seals, spark plugs, wires, water pump, and belts. Upgrading these components together can prevent future issues and improve overall reliability.

- Water Pump Modification:

- If replacing the water pump, tap the weep hole for a hose fitting to bypass the Optispark, which can help eliminate future leaks that could damage the Optispark unit.

By performing these steps regularly, you can maintain the original OEM Optispark with its high-quality Mitsubishi sensor, ensuring it remains in excellent condition, similar to maintaining a top-mounted distributor. This proactive approach can save money and extend the lifespan of your Corvette’s ignition system.

Important Background Information Related to the ECMs & Optisparks

It’s important to understand the differences between the ECMs & Optisparks for all years of the LT1 Engines.

The LT1 engine, produced by Chevrolet for various cars between 1992 and 1997, underwent significant changes over the years, particularly in the Optispark ignition system and the ECM (Engine Control Module). The differences between the 1992-1993, 1994-1995, and 1996 LT1 engines primarily involve improvements in reliability, emissions control, and diagnostics.

1992 and 1993 LT1 Engines (First Generation Optispark)

- Optispark:

- The Optispark ignition system is an optical distributor mounted at the front of the engine, driven off the camshaft.

- Design: In the 1992 and 1993 models, the Optispark was a first-generation system with a ventless design, meaning it had no venting system for moisture or ozone. This made it prone to moisture buildup, leading to failures when moisture entered the unit, which would cause misfires or ignition failure.

- Susceptibility to failure: It was located in an area of the engine that made it susceptible to problems from water or oil leaks. This early version of Optispark was less reliable due to poor sealing, and moisture could interfere with the optical sensor.

- ECM (Engine Control Module):

- The 1992 and 1993 models used an older ECM (ECM 8051), a more basic engine management system compared to later years.

- The ECM in these models had limited onboard diagnostics, lacking the OBD-II features introduced in later models. It was also slower in processing data and managing the engine’s performance.

- The ECM controlled fuel injection, spark timing, and emissions, but did not offer the more advanced capabilities of later versions like sequential fuel injection or real-time monitoring for enhanced diagnostics.

1994 and 1995 LT1 Engines (Second Generation Optispark and Updated PCM)

- Optispark:

- The 1994-1995 models featured a second-generation Optispark system with significant improvements over the earlier design.

- Ventilation: The new version was vented with a vacuum line and an air intake from the engine, allowing moisture and ozone to be expelled, which improved the durability of the system. This venting system helped reduce the moisture-related failures seen in the 1992-1993 models.

- Sealing: The Optispark was better sealed, leading to fewer issues with contamination from oil leaks or environmental moisture.

- PCM (Powertrain Control Module):

- Starting in 1994, the LT1 engines switched to the Powertrain Control Module (PCM 16188051), which was more advanced than the previous ECM.

- Sequential Fuel Injection: This PCM introduced sequential fuel injection (SFI) instead of the earlier batch-fire fuel injection. SFI allows for more precise fuel control, firing each injector independently based on the crank and camshaft positions.

- OBD-I Diagnostics: The 1994-1995 PCM was OBD-I compliant, offering more robust diagnostic capabilities compared to the earlier ECM. However, it was still not as advanced as OBD-II, which became standard in 1996.

1996 LT1 Engine (OBD-II and Improved Optispark)

- Optispark:

- The 1996 Optispark system was similar to the 1994-1995 vented version, but with some minor improvements.

- Vent and vacuum system: The venting system remained, and GM continued to fine-tune the sealing and moisture protection, though no major design overhaul occurred.

- Reliability improvements: Some minor improvements to the distributor cap and rotor materials were made, but the overall design was based on the second-generation Optispark introduced in 1994.

- PCM and OBD-II:

- The 1996 LT1 marked the transition to OBD-II (On-Board Diagnostics II), a significant change from the previous OBD-I system.

- OBD-II Compliance: OBD-II introduced real-time monitoring of emissions-related components and provided a standardized diagnostic system that allowed for more detailed information about the engine’s performance. This made it easier for mechanics to troubleshoot problems using a standardized scan tool.

- Enhanced PCM (Powertrain Control Module): The 1996 PCM was designed to meet OBD-II standards and provided even more precise control over fuel injection, ignition timing, and other engine functions. It also supported additional sensors, which improved emissions control and engine efficiency.

- Emissions Control: The OBD-II system monitored more parameters to ensure that emissions standards were being met, and it could detect failures like catalytic converter efficiency or fuel vapor leaks. This led to the installation of additional components like secondary oxygen sensors to monitor the performance of the catalytic converter.

Summary of Key Differences:

- Optispark Ignition System:

- 1992-1993: First-generation Optispark, ventless, prone to moisture and failure.

- 1994-1995: Second-generation Optispark, vented, more reliable with improved sealing.

- 1996: Further improvements to the second-generation Optispark with better reliability, but no major design changes.

- Engine Control Systems:

- 1992-1993: Used an older ECM with batch-fire injection and limited diagnostics (OBD-I).

- 1994-1995: PCM introduced with sequential fuel injection (SFI) and improved diagnostics (OBD-I).

- 1996: Upgraded PCM to comply with OBD-II, offering more precise control, enhanced emissions monitoring, and real-time diagnostics.

Why the Changes?

1996: Introduction of OBD-II for stricter emissions regulations and more advanced diagnostics, along with further refinement of the Optispark for improved durability.

1992-1993: Early design with some reliability issues, particularly with the Optispark.

1994-1995: GM made improvements to address the moisture issues in the Optispark and enhanced the engine management system with better fuel control and diagnostics.

Opti Mechanical Differences

There are mechanical differences in how the Optispark distributor connects to the camshaft between the 1992-1993 LT1 engines and the 1994-1996 LT1 engines. These differences are due to changes in the spline drive design, affecting compatibility between the two groups of years.

1992-1993 LT1 Optispark (First Generation) – Camshaft Drive:

- The 1992-1993 Optispark units use a single pin drive system.

- The Optispark distributor is mechanically connected to the camshaft via a single spline or pin that fits into the front of the camshaft.

- This setup is less robust and precise compared to later designs, which made it more prone to mechanical wear over time. If the pin or slot wore out or misaligned, it could cause issues with timing and the performance of the ignition system.

- This mechanical connection was specific to the early version of the Optispark, making the 1992-1993 Optispark incompatible with the camshaft used in later LT1 engines (1994-1996) unless the camshaft or drive mechanism was modified.

1994-1996 LT1 Optispark (Second Generation) – Camshaft Drive:

- The 1994-1996 Optispark units use a reluctor or splined drive system.

- Starting in 1994, GM improved the mechanical connection by switching to a more robust spline drive system. This splined connection provided a stronger, more durable engagement between the camshaft and the Optispark distributor.

- The spline drive is more precise and reduces the chances of mechanical wear and misalignment, which were issues with the single-pin drive system used in the earlier models.

- As a result, the 1994-1996 Optispark distributors are not interchangeable with the 1992-1993 versions unless you swap the camshaft or the drive mechanism to match the Optispark’s design.

Why the Change?

- Improved durability and precision: The change from a single-pin drive to a splined drive was aimed at improving the durability and mechanical reliability of the Optispark connection. The spline design helps ensure a better fit and more consistent operation over time, addressing issues like wear or timing misalignment that were more common in the earlier models.

Compatibility Note:

- The mechanical differences mean that the 1992-1993 Optispark distributors are not directly compatible with 1994-1996 LT1 engines, and vice versa, unless you modify the camshaft or use the appropriate generation of Optispark for your specific engine year.

Summary of Spline Differences:

- 1992-1993 Optispark: Uses a single-pin drive system to connect to the camshaft.

- 1994-1996 Optispark: Uses a splined drive system, which is more durable and precise.

This difference in mechanical design is one of the key reasons why the 1992-1993 and 1994-1996 Optisparks are not interchangeable without significant modifications.

Fuel System Differences

When comparing batch and sequential fuel injection (SFI) in the context of the 1992-1996 Corvette LT1 engine, the consensus is that sequential fuel injection (SFI), which was introduced in the 1994 model year, offers advantages for performance, fuel efficiency, and emissions over batch fire injection, which was used in the 1992-1993 models.

Batch Fire Injection (1992-1993 LT1)

- How It Works:

- In batch fire injection, the fuel injectors fire in groups (or batches) rather than individually.

- All injectors on one bank of the engine fire at the same time, regardless of the position of the individual cylinder’s intake valve. Some injectors will spray fuel when the intake valve is open, and others will spray when it’s closed, resulting in the fuel waiting in the intake port for the valve to open.

- Performance Impact:

- Less precise fuel delivery: Since the injectors fire without considering the exact timing of the intake valve’s opening, batch injection can lead to less efficient fuel atomization and potentially more unburned fuel.

- Lower fuel efficiency: The system is less efficient compared to SFI because fuel isn’t always injected at the optimal time. This can result in uneven combustion and increased emissions.

- Reduced low-RPM performance: At lower engine speeds, batch injection can result in sluggish throttle response and less efficient combustion, affecting both power delivery and throttle feel.

- Simpler and less costly: Batch fire injection systems are generally simpler and less expensive to produce but lack the refined control needed for higher performance applications.

Sequential Fuel Injection (SFI) (1994-1996 LT1)

- How It Works:

- In sequential fuel injection, each injector fires individually, timed specifically to match the opening of the intake valve for each cylinder. This is much more precise because the fuel is injected exactly when the engine needs it.

- The PCM (Powertrain Control Module) monitors the position of the crankshaft and camshaft to ensure that fuel is delivered to each cylinder at the ideal moment during the intake stroke.

- Performance Impact:

- More precise fuel delivery: SFI ensures that the fuel is injected right as the intake valve opens, leading to better atomization and more efficient combustion.

- Improved fuel efficiency: Since fuel is delivered at the optimal time, SFI reduces waste and improves the air-fuel mixture, leading to better fuel economy and lower emissions.

- Better throttle response: SFI offers more precise control over fuel delivery, leading to smoother and more responsive throttle action, especially at lower RPMs, where batch fire systems may feel sluggish.

- More power potential: By optimizing fuel delivery for each cylinder, SFI can offer a modest improvement in horsepower and torque, especially under high-load conditions where precise fuel control is critical.

Performance Comparison:

- Fuel Efficiency:

- SFI: More efficient due to precise timing of fuel delivery, leading to better fuel atomization and reduced fuel waste. This translates into better fuel economy and lower emissions.

- Batch Fire: Less efficient, with fuel injected whether or not the cylinder is ready to burn it, leading to some fuel waiting in the intake port, which can cause less consistent combustion.

- Throttle Response:

- SFI: Offers better throttle response, especially at lower RPMs, where the precision of fuel delivery improves the smoothness of power delivery.

- Batch Fire: Can feel less responsive, particularly at lower engine speeds, where the imprecise timing of fuel injection results in uneven power delivery.

- Power Output:

- SFI: Sequential injection may yield a slight increase in horsepower and torque due to improved fuel control and combustion efficiency, particularly at higher RPMs or under load.

- Batch Fire: Typically does not offer the same level of control, which can result in marginally lower power output compared to SFI.

- Emissions and Smoothness:

- SFI: Reduces emissions due to more complete and efficient combustion. Also contributes to a smoother running engine with fewer fluctuations in performance.

- Batch Fire: Less optimized for emissions and can result in slightly rougher engine performance, especially in cold start conditions.

Conclusion: SFI vs. Batch Fire Injection for Performance

For performance, sequential fuel injection (SFI), which was introduced in the 1994-1996 LT1 engines, is the superior option. Its precise control over fuel delivery improves fuel atomization, combustion efficiency, throttle response, and overall engine performance. While batch fire injection (1992-1993 LT1) is simpler and functional, it lacks the fine control that SFI offers, resulting in lower fuel efficiency, slightly less power, and slower throttle response.

If performance is the primary goal, SFI is the better choice, offering better fuel management and improved engine performance in various driving conditions. This is why the 1994-1996 Corvette LT1 engines are more refined and offer better overall drivability than their 1992-1993 counterparts.

You must be logged in to post a comment.